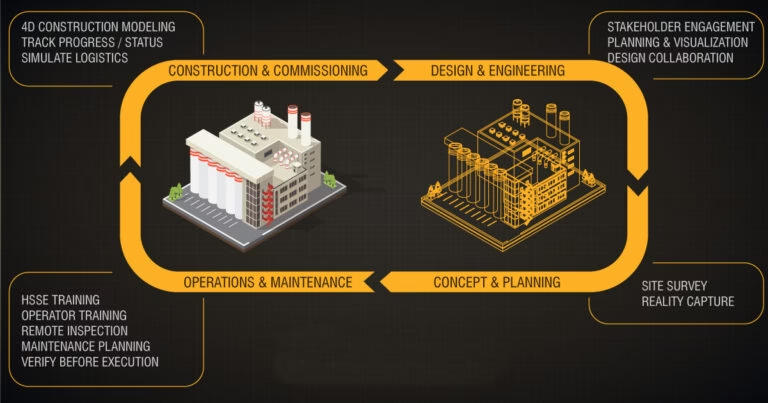

In my extensive experience in the construction industry, I’ve witnessed how Digital Twin technology is revolutionizing project management and operations. Digital Twin technology creates a precise virtual replica of physical assets, integrating real-time data to enhance decision-making and project efficiency. As construction projects become increasingly complex, understanding and implementing Digital Twins can provide significant advantages. This technology allows us to monitor, analyze, and optimize every aspect of a project, from initial design through to maintenance, leading to improved outcomes and reduced costs.

Overview

The implementation of Digital Twin technology in construction offers numerous benefits, including enhanced visibility, predictive maintenance, and optimized resource management. However, it also presents challenges such as data integration and high initial costs. To effectively leverage Digital Twins, it’s essential to understand the technological requirements and tools necessary for successful implementation. Case studies illustrate how Digital Twins have been applied in real-world projects, showcasing their potential to transform construction practices. By following best practices and staying informed about future trends, construction professionals can harness the full power of Digital Twins to drive innovation and efficiency.

What is a Digital Twin?

In my extensive experience in the construction industry, I’ve observed how Digital Twin technology is reshaping our approach to managing projects. A Digital Twin is essentially a sophisticated virtual model that mirrors the physical world. It integrates data from sensors, Building Information Modeling (BIM), and other sources to create a dynamic and real-time digital representation of a construction asset or system. This virtual model reflects the exact state and behavior of its physical counterpart, allowing us to monitor and analyze performance in ways that were previously unimaginable. For construction professionals, Digital Twin technology offers a comprehensive view of a project’s lifecycle—from initial design through to construction, operation, and maintenance. It enables us to simulate scenarios, predict outcomes, and make informed decisions based on real-time data. By utilizing Digital Twins, we can enhance project planning, improve operational efficiency, and address issues proactively, ultimately leading to better project outcomes and optimized resource management. This technology stands at the forefront of digital transformation in construction, offering unprecedented insights and capabilities for effective project management.

Benefits of Digital Twin in Construction

From my extensive experience in the construction field, the benefits of incorporating Digital Twin technology into our projects are both profound and transformative. Digital Twin technology provides a highly detailed and accurate digital replica of a construction asset, allowing us to visualize and analyze every aspect of a project in real-time. This enhanced visibility significantly improves decision-making, as we can monitor progress, predict potential issues, and test various scenarios before implementing changes on-site. By integrating real-time data from sensors and BIM models, Digital Twins enable us to optimize resource allocation, streamline operations, and reduce costs. Additionally, this technology facilitates proactive maintenance by predicting equipment failures and identifying potential problems before they escalate. The ability to simulate different scenarios and assess their impact also enhances risk management and project planning. Overall, Digital Twin technology fosters greater efficiency, accuracy, and collaboration, leading to improved project outcomes and more informed strategic decisions. Its application represents a significant advancement in construction management, driving innovation and efficiency across the industry.

Challenges in Implementing Digital Twin

In my experience working with Digital Twin technology in construction, I’ve encountered several challenges that can complicate its implementation. One major hurdle is the integration of various data sources. Digital Twins rely on comprehensive data from sensors, BIM models, and other inputs to accurately reflect the physical asset, and ensuring seamless integration of these diverse data streams can be complex and time-consuming. Additionally, maintaining data accuracy and consistency is crucial; any discrepancies between the digital model and the physical asset can undermine the technology’s effectiveness. Another challenge is the initial cost and effort involved in setting up a Digital Twin system. The need for advanced technology, skilled personnel, and ongoing maintenance can be significant barriers, particularly for smaller firms. Furthermore, as with any technology, there is a learning curve associated with using Digital Twins effectively. Training staff to utilize and interpret the data correctly is essential for maximizing the benefits of this technology. Despite these challenges, the potential of Digital Twins to transform construction project management remains substantial. Addressing these issues proactively can lead to more successful implementation and harness the full power of Digital Twin technology.

Technological Requirements and Tools

In my experience with Digital Twin technology in construction, understanding the technological requirements and tools necessary for successful implementation is crucial. A robust Digital Twin system requires a combination of advanced hardware and software. Key components include high-resolution sensors and IoT devices to capture real-time data from the physical asset. These sensors feed data into a central platform where Building Information Modeling (BIM) software integrates and visualizes this information in a digital format. Additionally, cloud computing infrastructure is essential for storing and processing the vast amounts of data generated, allowing for scalable and accessible digital models. Advanced analytics and simulation tools further enhance the functionality of Digital Twins by providing insights into performance, predictive maintenance, and scenario planning. Additionally, data management and integration tools play a vital role in ensuring that the digital model accurately reflects changes in the physical asset. Training and skilled personnel are also critical, as utilizing these tools effectively requires expertise in both the technology and its applications. By investing in the right technological tools and ensuring proper integration, construction professionals can fully leverage Digital Twin technology to improve project management and operational efficiency.

Case Studies and Examples

From my extensive experience in the construction industry, I’ve seen several compelling case studies that highlight the impact of Digital Twin technology. One notable example is the implementation of Digital Twin at the Hudson Yards development in New York City. Here, Digital Twin technology played a pivotal role in managing this massive urban redevelopment project. By integrating real-time data from sensors and BIM models, the project team was able to optimize construction processes, monitor structural health, and enhance facility management. Another illustrative case is the use of Digital Twins in the London Crossrail project. This technology allowed for detailed simulation and analysis of construction processes, helping to streamline operations and address potential issues before they arose. The application of Digital Twin technology also extended to the operational phase, where it facilitated ongoing maintenance and performance monitoring. These examples demonstrate how Digital Twin technology can drive efficiency, reduce costs, and improve decision-making across various stages of construction projects. By leveraging Digital Twins, construction professionals can achieve greater control and insight, ultimately leading to more successful project outcomes.

Best Practices for Implementation

Drawing from my experience with Digital Twin technology in construction, implementing it successfully requires a strategic approach and adherence to best practices. First, start by defining clear objectives and scope for the Digital Twin. This helps ensure that the digital model aligns with project goals and provides relevant insights. It’s essential to invest in high-quality sensors and IoT devices to capture accurate and comprehensive data from the physical asset. Integrate this data seamlessly with Building Information Modeling (BIM) software to create a cohesive digital representation. Establish robust data management practices to maintain the accuracy and consistency of the digital model, and ensure that data integration tools effectively synchronize real-time updates. Additionally, invest in training for your team to effectively use and interpret the Digital Twin, as skilled personnel are crucial for maximizing its benefits. Regularly update and maintain the Digital Twin to reflect changes in the physical asset, and leverage advanced analytics to derive actionable insights. Finally, foster collaboration among stakeholders by sharing access to the Digital Twin, which enhances communication and coordination throughout the project lifecycle. By following these best practices, construction professionals can harness the full potential of Digital Twin technology to improve project efficiency, decision-making, and overall outcomes.

Future Trends and Developments

As an experienced construction professional, I see exciting developments on the horizon for Digital Twin technology. The future of Digital Twins in construction will likely involve deeper integration with emerging technologies such as artificial intelligence (AI) and machine learning. These advancements will enhance predictive analytics, enabling more accurate forecasting and proactive decision-making. Additionally, the integration of augmented reality (AR) and virtual reality (VR) with Digital Twins will provide immersive, interactive experiences, allowing project stakeholders to visualize and interact with digital models in real time. As data collection technologies evolve, we can expect even more detailed and precise Digital Twins, driven by advancements in sensor technology and IoT devices. Furthermore, the increasing adoption of blockchain technology may improve data security and transparency within Digital Twin systems, ensuring reliable and tamper-proof records. The growing emphasis on sustainability will also drive the development of Digital Twins that focus on environmental impact and energy efficiency. These future trends promise to significantly enhance the capabilities of Digital Twin technology, offering construction professionals advanced tools for optimizing project management, reducing costs, and improving overall project outcomes.

Conclusion

In conclusion, Digital Twin technology represents a significant advancement in the construction industry, offering the ability to manage projects with unprecedented precision and insight. By overcoming implementation challenges and adopting best practices, construction professionals can fully exploit the benefits of Digital Twins. As the technology continues to evolve, staying abreast of future trends and developments will be crucial for maintaining a competitive edge. Embracing Digital Twins not only enhances project management but also paves the way for a more efficient and innovative approach to construction. As we look to the future, integrating Digital Twin technology will undoubtedly play a key role in shaping the next generation of construction practices.

Further Reads

For those interested in diving deeper into Digital Twin technology and its application in construction, several resources offer valuable insights and advanced knowledge. “Digital Twin Driven Smart Design” by Fei Tao, Ang Liu, Tianliang Hu, A.Y.C. Nee. provides a comprehensive overview of how Digital Twin technology integrates with smart design principles, offering practical examples and case studies. Journals such as the Journal of Construction Engineering and Management frequently publish articles on the latest advancements and real-world applications of Digital Twins in construction projects. For industry-specific updates and trends, the Construction Innovation magazine covers the latest developments in Digital Twin technology and its impact on the construction industry. Engaging with these resources will deepen your understanding of Digital Twins and provide you with cutting-edge knowledge to apply in your construction projects, ultimately leading to more informed decisions and successful project outcomes.

Leave a Reply